Keeping tools and equipment clean can take a lot of time, especially when dealing with parts that have small crevices or stubborn buildup. Traditional cleaning methods often leave behind residue or require harsh chemicals. An ultrasonic cleaner makes the process faster, more precise, and easier for any workshop.

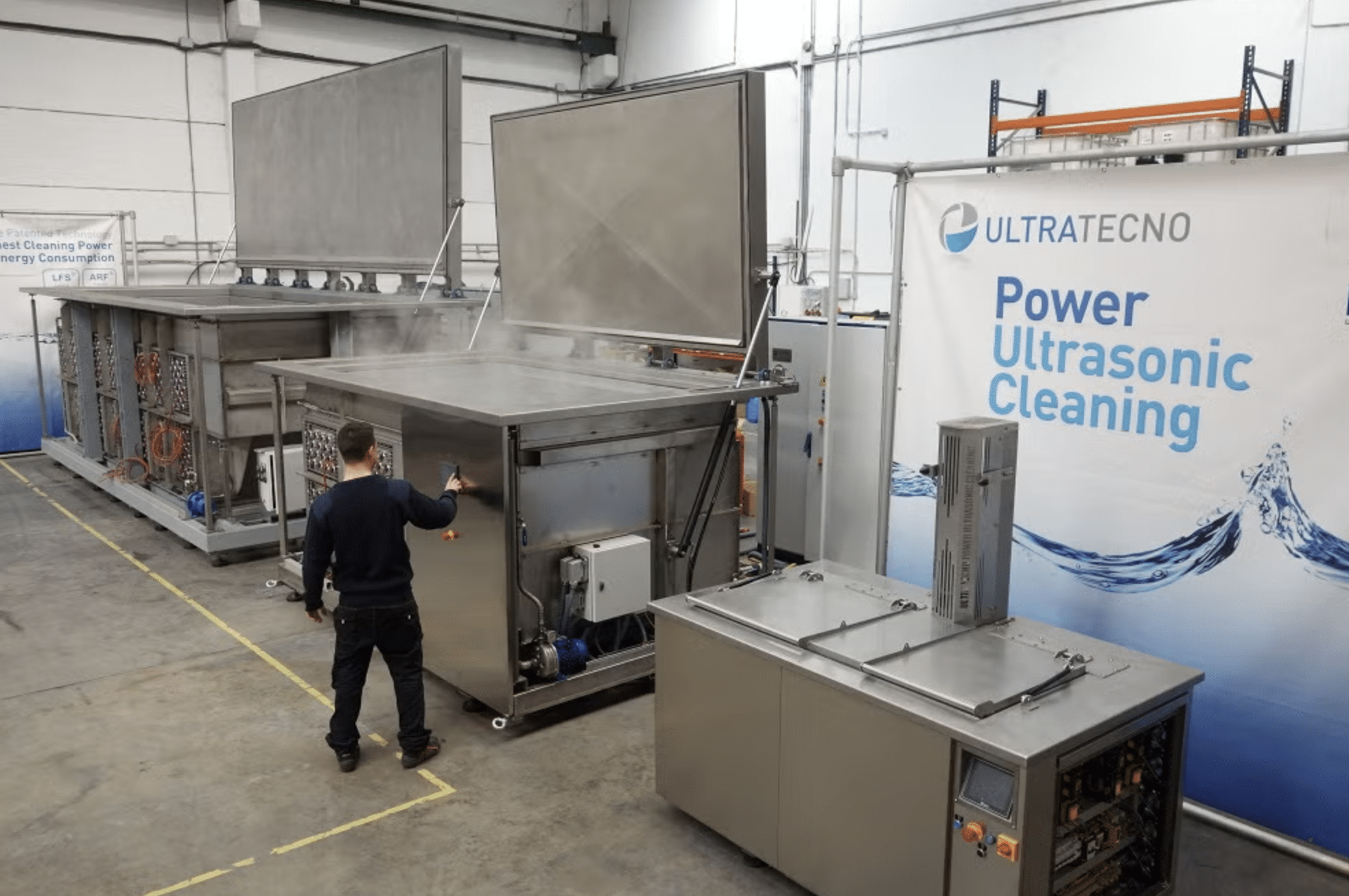

By using sound waves in a cleaning solution, this technology removes dirt, grease, and other particles that are hard to reach by hand. A unit like the VEVOR 30L ultrasonic cleaner can handle larger parts or multiple items at once, making it practical for both small tasks and bigger projects. This means less time spent scrubbing and more time focusing on actual work.

Workshops that use ultrasonic cleaners also benefit from reduced chemical use, which helps lower costs and makes the space safer to work in. The equipment provides consistent results, so tools and components stay in better condition for longer.

Key Takeaways

- Ultrasonic cleaners save time and improve cleaning results

- They support safer and more efficient workshop practices

- Larger units handle multiple parts for added convenience

Key Benefits of Owning an Ultrasonic Cleaner for Your Workshop

An ultrasonic cleaner offers strong cleaning power, saves time, and reduces manual effort. It also helps protect delicate parts, lowers costs over time, and provides consistent results for both small and complex items.

Superior Cleaning Performance

An ultrasonic cleaner uses high-frequency sound waves to create tiny bubbles in a cleaning solution. These bubbles collapse with force, loosening dirt, grease, and other contaminants from surfaces. This process, called cavitation, reaches areas that brushes or sprays cannot access.

The cleaning process works well on items with holes, grooves, or tight spaces. For example, carburetor parts, fine tools, and small machine components often trap residue in areas that are hard to scrub by hand.

Unlike traditional cleaning methods, ultrasonic cleaning provides even results across the entire surface. The same action happens inside every corner of the part, giving a uniform finish. This makes it especially useful for workshops that deal with precision equipment.

Time and Labor Efficiency

Manual scrubbing and soaking often take hours, especially when dealing with multiple parts or stubborn buildup. An ultrasonic cleaner reduces this workload by handling the cleaning process automatically.

Most machines only require the user to fill the tank, add solution, and set the timer. Once started, the ultrasonic cleaner does the rest without constant supervision. This frees workers to focus on other tasks in the workshop.

The process also shortens turnaround time. A batch of tools that might take an entire afternoon to clean by hand can often be cleaned in less than an hour. This efficiency makes it easier to keep tools and equipment ready for use.

Gentle Yet Thorough Cleaning

While ultrasonic cleaning is powerful, it does not rely on harsh scrubbing or abrasive methods. The bubbles created during cavitation are small enough to clean delicate surfaces without scratching or damaging them.

This makes ultrasonic cleaners useful for items like precision instruments, fine metal parts, and components with coatings that should not be disturbed. Even fragile materials can be cleaned thoroughly without risk of bending or wear.

The process also reduces the need for strong chemical cleaners. Many items can be cleaned effectively with mild solutions, which lowers the chance of corrosion or surface damage. For workshops handling both sturdy and delicate parts, this balance of strength and care is a major advantage.

Enhanced Energy and Cost Savings

Although an ultrasonic cleaner requires an initial purchase, it often lowers costs over time. Less labor is needed for cleaning, and fewer harsh chemicals are required. This reduces both supply expenses and disposal needs.

The machines also use less water compared to soaking or pressure washing methods. Because the cleaning process is faster, energy use is often lower as well.

In a workshop, this means reduced operating costs and less waste. Over months or years, the savings in time, materials, and energy can outweigh the upfront price of the equipment. For many users, the cleaner becomes a long-term investment that supports both productivity and budget control.

Additional Advantages for Workshop Applications

An ultrasonic cleaner offers more than just speed and precision. It also supports cleaner practices, handles intricate parts with ease, and helps keep tools in good condition for longer use.

Eco-Friendly Cleaning Solutions

The ultrasonic cleaning process uses water-based solutions instead of harsh chemicals. This reduces the amount of toxic waste produced in a workshop. It also lowers the risk of chemical exposure for workers, making the environment safer.

Many cleaning tasks that once required strong solvents can now be handled with mild detergents. This means less air pollution from fumes and fewer disposal problems.

Workshops that use ultrasonic cleaning often save money on chemical purchases and waste management. By cutting down on solvent use, they also meet safety and environmental standards more easily.

Ability to Clean Complex Parts

Traditional cleaning methods struggle with small openings, fine grooves, and detailed surfaces. An ultrasonic cleaner reaches these areas by sending high-frequency sound waves through the cleaning solution. The waves create microscopic bubbles that remove dirt and debris from every surface.

This process is especially useful for tools, machine parts, and components with hidden passages. Even items with oil, grease, or machining residue come out clean without the need for scrubbing.

For workshops that handle a variety of parts, ultrasonic cleaning provides consistent results. Larger units, such as a 30L ultrasonic cleaner, can handle multiple items at once, saving time and effort.

Extended Component Lifespan

Manual scrubbing and abrasive chemicals can wear down surfaces over time. Ultrasonic cleaning avoids this problem by using a non-contact process that does not scratch or damage materials.

Because the cleaning process is gentle, workshop tools and parts maintain their original finish longer. This helps reduce the need for replacement and lowers operating costs.

Regular ultrasonic cleaning also prevents buildup of grease, rust, and other contaminants. By keeping parts in better condition, the equipment functions more smoothly and lasts longer, improving overall workshop efficiency.

Conclusion

An ultrasonic cleaner gives workshops a simple way to handle cleaning tasks that would normally take much more time and effort. It works well on delicate parts, detailed surfaces, and items with hard-to-reach areas.

By using sound waves and cleaning solution, it removes dirt, grease, and residues without damaging the material. This makes it useful for tools, machinery parts, and precision items.

The main benefits include:

- Time savings

- Gentle cleaning

- Ability to clean complex shapes

- Lower labor needs

- Cost efficiency

For many workshops, this tool provides a practical balance of speed, safety, and effectiveness. It supports cleaner equipment, longer part life, and less manual effort.